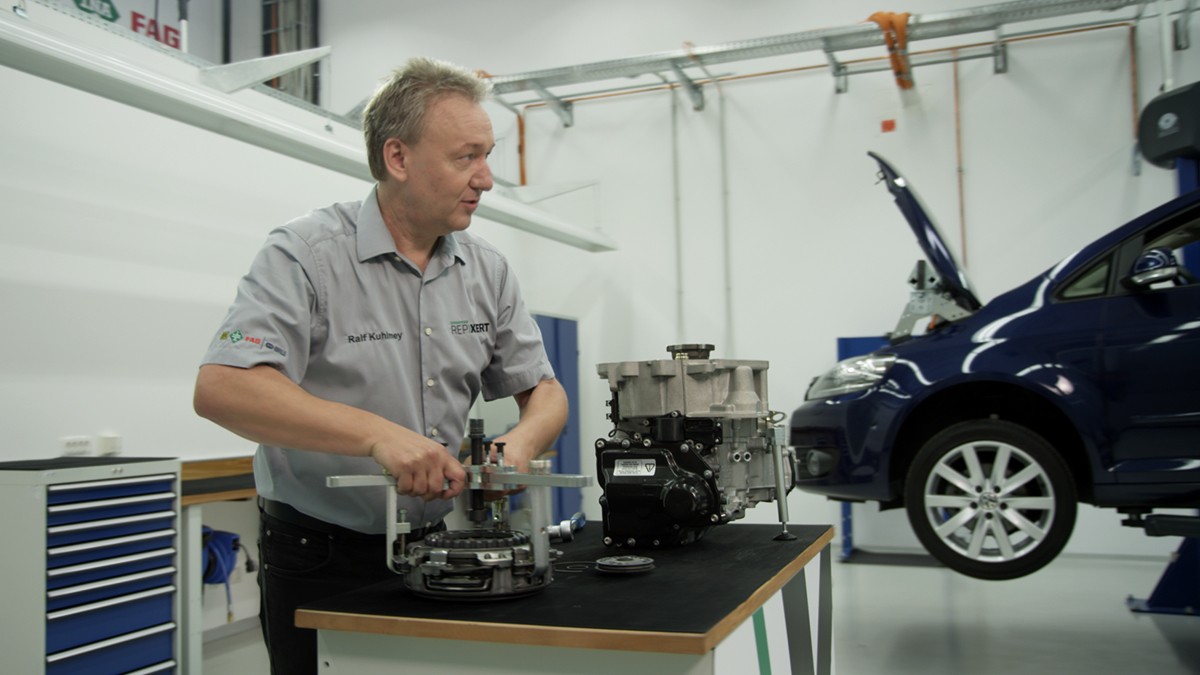

Stories from Schaeffler: Technology and Systems Expertise

Further thinking, lateral thinking, and rethinking allow us to identify key trends at an early stage. We develop innovative products and systems, define new technology standards, and make them ready for volume production.