HERAQCLES

HERAQCLES stands for new manufacturing approaches for Hydrogen Electrolysers to provide Reliable AEM technology-based solutions while achieving Quality, Circularity, low LCOH, high Efficiency and Scalability.

Project description

The HERAQCLES project aims to develop an innovative anion exchange membrane (AEM) technology that uses a design-for-manufacturing architecture and newly developed components. This approach also seeks to overcome stack manufacturing process bottlenecks, improve cost efficiency and enhance overall performance. The project’s objectives include advancing manufacturing readiness level, enhancing components to comply with a concept for automation at industrial scale, and validating the solution with a focus on improving sustainability, recyclability and quality.

The project has received funding from the Fuel Cells and Hydrogen 2 Joint Undertaking (now Clean Hydrogen Partnership) under Grant Agreement No 101111784. This Joint Undertaking receives support from the European Union’s Horizon 2020 Research and Innovation programme, Hydrogen Europe and Hydrogen Europe Research.

Further informationen

Electrolysis can ensure the success of the energy transition | medias

Objectives

The project HERAQCLES has the ambition to deliver an operational 25kW electrolyser stack by 2027, including balance-of-plant based on AEM technology to validate both our novel design-for-manufacturing architecture and innovative components developed for automated production processes. AEM electrolysis offers a more attractive cost/performance ratio compared to state-of-art PEM electrolysis because these is no need to utilise precious group metals in stack components like catalysts, porous transport layers and bipolar plates for generating hydrogen at reasonably high current density.

Public reports

Work package 1 - project management

Work package 4 - development of catalyst coated PTLs and MEA formation

Work package 5 - stack hardware development and manufacturing

Work package 7 - communication, dissemination, IP exploitation, synergies

Consortium

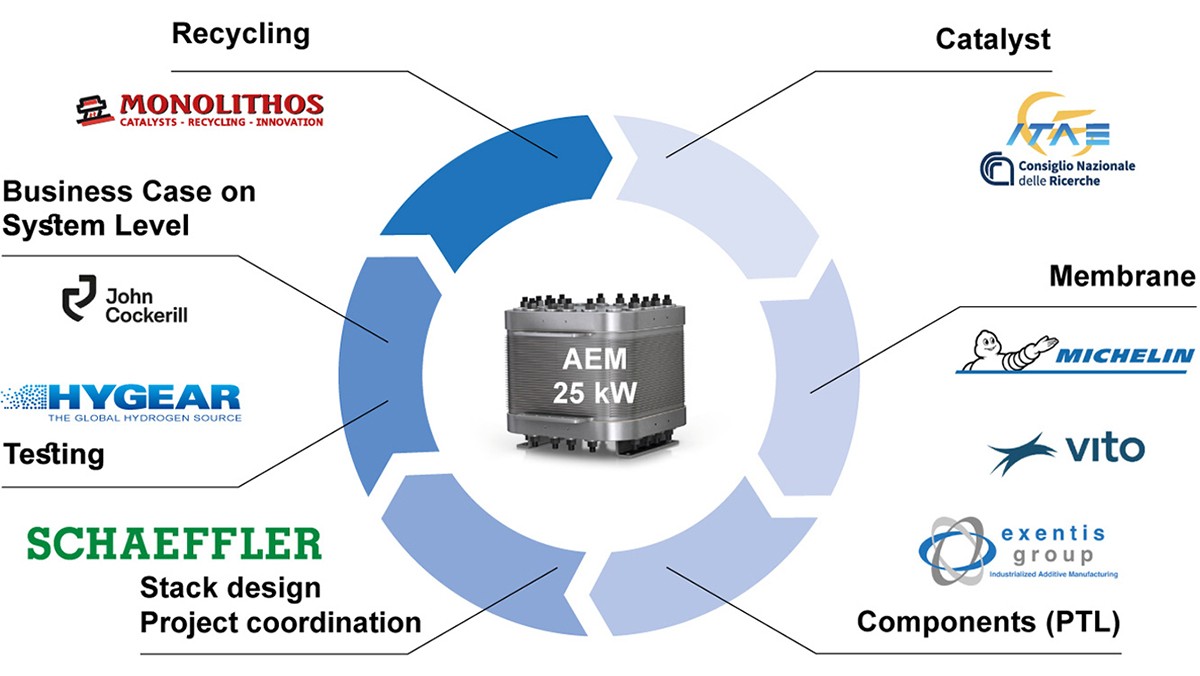

HERAQCLES is a joint project, funded by the Clean Hydrogen Joint Undertaking, coordinated by Schaeffler Technologies AG & Co. KG that gathers research and industrial partners:

- Consiglio Nazionale delle Ricerche (Italy)

- VITO – Vlaamse Instelling voor Technologisch Onderzoek (Belgium)

- Manufacture Française des Pneumatiques Michelin (France)

- HYGEAR B.V. (Netherlands)

- MONOLITHOS Catalysts and Recycling Ltd (Greece)

- Exentis Technology GmbH (Germany)

- John Cockerill Hydrogen (Belgium)

The experienced consortium brings together a unique combination of know-hows and manufacturing capabilities provided by strong representation from industrial partners.

News & Events

5th consortium meeting after 24 months of project duration in Clermont Ferrand

The 5th progress meeting took place on June 5th at the facilities of Michelin in Clermont Ferrand. This hybrid meeting allowed partners to discuss the project’s significant advancements and milestones reached:

- An innovative process for manufacturing highly performing reinforced AEM hydrocarbon membrane have been established.

- The stack prototype is ready for testing.

- The test rig is about to be finalized, tests will start soon.

M12 consortium meeting in Athens

The M12 progress meeting for the EU funded project HERAQCLES project took place on June 26th and 27th 2024 at the facilities of Monolithos Catalysts & Recycling Ltd. in Athens. In this hybrid meeting, partners participated both onsite and online to discuss the significant advancements of the project. During this productive session, insightful discussions were held, and innovative ideas were worked on.

HERAQCLES partners were able to experience a live demonstration of Monolithos hydrometallurgical leching method for recycling electrocatalysts from AEM electrolyser´s membrane electrode assemblies (MEAs), ensuring perspectives for second-life application.

Contact

Birgit Fischer

Funding Strategy – Public Funding

Dr. Peter Bouwman

Head of R&D Hydrogen