Simulation technologies in chassis technology

Schaeffler is involved in virtual motor sport for the first time: The global automotive and industrial supplier demonstrates its core expertise through its sim racing partnership with Coanda Simsport: The latest simulation technologies help to develop optimally designed components and systems - in the field of chassis systems, for example.

Gaining an understanding of the entire vehicle level

In the field of chassis systems, simulation technologies facilitate effective and efficient product development. The objective here is to analyze and gain an understanding of the entire vehicle level. In product development, Schaeffler engineers simulate entire vehicles using complex behavior models in various programs. Products such as the mechatronic active roll control system are integrated into the simulation in order to further improve the vehicle’s driving behavior.

Safe driving behavior in the event of a failure

In addition to high performance, development engineers also focus on vehicle behavior in the event of a failure. Vehicle simulations enable failures to be analyzed without damaging components or risking the loss of human life. The functional safety classification is a crucial factor affecting development costs and is therefore a particularly important aspect.

Merging simulation with reality

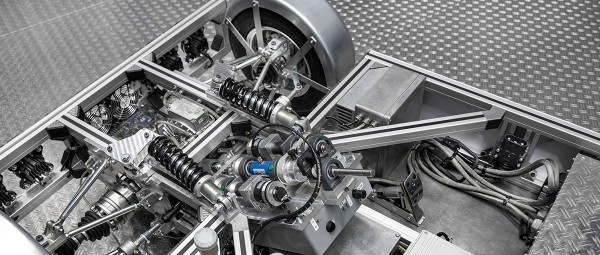

In addition to approaches based purely on simulation, combined methods using experimental setups are also becoming increasingly important. A combined method can, for example, be used during the early phase of product development in the form of a test rig with environment simulation and a prototype control unit. Assessments of the steering feel (driver-in-the-loop method) and test phases for ensuring the function of a volume-produced control unit or an entire volume-produced product (x-in-the-loop method) are also possible.